Complete guide on how to import solar panel manufacturing machines from China, with machine list, setup cost, floor plan, and legal requirements in India.

How to Import Solar Panel Manufacturing Machines from China – Step-by-Step Guide

🇨🇳 Why Choose China for Solar Panel Machinery?

China leads the world in manufacturing solar equipment. Reliable OEMs like Zenith, Radiant, and Fengyang provide full production lines that come CE/ISO certified, with global support and fast delivery.

📦 Full Machine List with Cost Estimates

| Machine | Function | Estimated Cost (INR) |

|---|---|---|

| Solar Cell Stringer | Solders cells into strings | 18–30 L |

| Layup Table | Manual placement of EVA, glass | 1–2 L |

| Laminator | Laminates the panel | 25–45 L |

| Framing Machine | Frame installation | 5–8 L |

| Sun Simulator | Panel output test | 10–20 L |

| IV/EL Tester | Check panel quality | 6–10 L |

More machines and details can be explored on

💰 Total Investment Breakdown

- Machines: ₹1.5–2.5 Cr

- Factory: ₹60–80 L (20,000 sq ft)

- Electricals/Power: ₹10–15 L

- Duties/Freight: ₹10–20 L

- Installation/Training: ₹5–10 L

- Raw Materials: ₹1–1.5 Cr

- Licenses & Consultants: ₹5–8 L

- Working Capital: ₹25–50 L

Total Estimate: ₹3.5–5 Cr for a 25–50 MW/year unit.

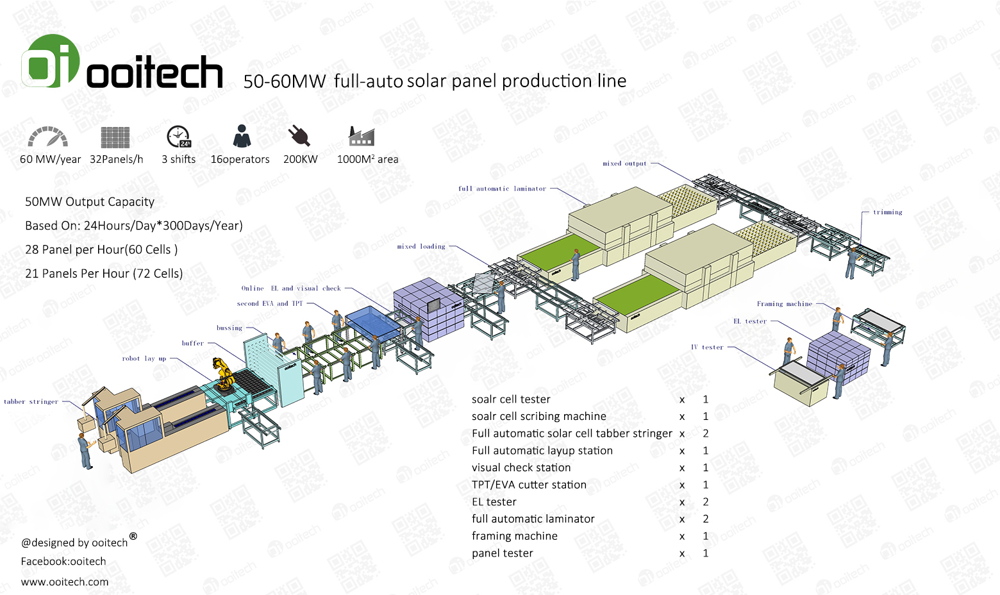

🏢 Floor Plan Layout

A plant typically includes zones for raw material, stringing, lamination, testing, framing, and packing. Minimum 15,000–20,000 sq. ft. is ideal with 50–80 kW power load.

🚢 Import Process from China

- Research suppliers (Alibaba, Made-in-China)

- Request quote and specifications (CIF)

- Verify certifications (CE, ISO)

- Book freight & customs clearance

- Get BIS approvals if applicable

- Install & train your team

Example supplier listing: lashonda.en.made-in-china.com

🔒 Licenses You Need in India

- Factory License

- GST & Udyam Registration

- Import Export Code (IEC)

- BIS Approval (if required)

- Pollution Control (if applicable)

⚠️ Mistakes to Avoid

- Importing uncertified or outdated machines

- Ignoring floor layout planning

- Underestimating duties and freight

- Skipping technician training

📅 Conclusion

Importing solar manufacturing machines from China is a smart way to build cost-effective and high-capacity solar plants in India. With proper planning, verification, and setup, your plant can be ready in 3–5 months.

Need help setting up your solar manufacturing business? Contact AUTIGO – your solar industry partner.